Charts

How To Make Enamel Pins: A Comprehensive Guide

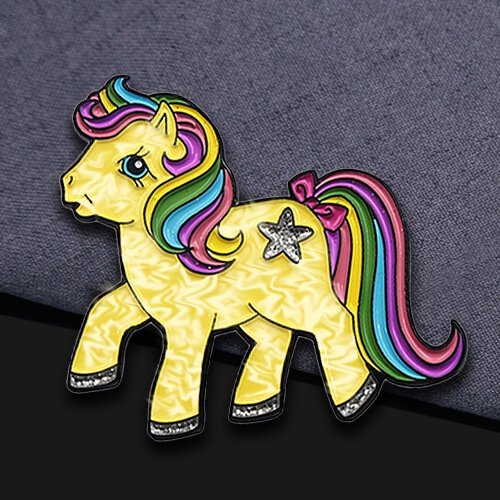

Enamel pins have become popular for their versatility, durability, and ability to showcase intricate designs. Whether you’re creating them for personal collection, brand promotion, or event souvenirs, understanding the production process is key. Below is a step-by-step guide to making enamel pins, along with their features, usage scenarios, and details about customization through QIYI-GIFTS.

The Process of Making Enamel Pins

- Design Finalization: The first step is to create or refine the design. This can be done using graphic design software, ensuring the artwork is clear, with distinct lines and colors. Simple or complex designs work, but finer details may require adjustments to fit the manufacturing process.

- Die Creation: Once the design is confirmed, a metal die is made. This die acts as a mold, shaping the metal base of the pin. The die is crafted with precision to match the design’s contours, ensuring accurate replication.

- Metal Stamping: A metal sheet (often brass, iron, or zinc alloy) is stamped using the die. This process creates the pin’s base, with raised and recessed areas that will later hold the enamel.

- Plating: The stamped metal base is plated to enhance its appearance and durability. Common plating options include gold, silver, nickel, or black nickel, which add a polished finish and prevent tarnishing.

- Enamel Application: Enamel paste, available in a wide range of colors, is applied to the recessed areas of the metal base. For hard enamel pins, the enamel is filled to the same level as the raised metal edges. For soft enamel pins, the enamel sits slightly lower, leaving the metal edges raised.

- Baking: The pins are baked in an oven at high temperatures. This process hardens the enamel, creating a lustrous finish and ensuring durability. Hard enamel pins undergo multiple baking cycles to ensure a smooth, even surface.

- Polishing: After firing, hard enamel pins are polished to remove excess enamel and create a flat, smooth surface where the metal and enamel meet. Soft enamel pins typically skip this step, retaining their textured look.

- Attachment Addition: Finally, backings (such as butterfly clutches, rubber clutches, or pinbacks) are added to allow the pin to be worn or displayed.

Features of Enamel Pins

- Durable: The firing process makes enamel resistant to scratches, fading, and daily wear, ensuring the pins last for years.

- Vibrant Colors: Enamel comes in a vast spectrum of hues, allowing for bold, eye-catching designs that retain their brightness over time.

- Versatile Designs: From simple logos to intricate artworks, enamel pins can accommodate various design complexities, making them suitable for diverse purposes.

- Two Main Types: Hard enamel pins have a smooth, flat surface with enamel flush to the metal edges, offering a high-end, jewelry-like feel. Soft enamel pins have a textured surface with raised metal edges, providing a more tactile, budget-friendly option.

Usage Scenarios

- Brand Promotion: Businesses use enamel pins to showcase logos, slogans, or brand mascots. They’re distributed at trade shows, given as employee gifts, or included with product purchases to boost brand visibility.

- Event Souvenirs: Concerts, festivals, conferences, and charity events often create custom enamel pins as keepsakes. Attendees can wear them to commemorate the occasion or add them to collections.

- Fashion Accessories: Enamel pins are a trendy way to personalize clothing, backpacks, hats, or jackets. They allow individuals to express their personality, interests, or affiliations.

- Collectibles: Limited-edition or artist-designed enamel pins are highly sought-after by collectors. Themes range from pop culture and nature to hobbies and social causes.

- Team or Group Identification: Clubs, sports teams, or organizations use enamel pins to foster a sense of unity. Members wear them to show belonging and pride.

Custom Enamel Pins with QIYI-GIFTS

QIYI-GIFTS specializes in creating high-quality custom enamel pins tailored to your needs. Whether you’re looking for hard or soft enamel, they offer a seamless customization process with the following advantages:

- Expert Design Support: Their team of designers works with you to refine your ideas, ensuring the final design translates perfectly into a pin. They handle everything from adjusting details to selecting the right colors.

- Flexible Options: Choose from various metals, platings, sizes, and backings to match your vision. They cater to both small batches and large orders, with no minimum quantity restrictions for most projects.

- Quality Assurance: QIYI-GIFTS uses premium materials and strict manufacturing standards to ensure each pin meets high-quality benchmarks, from the clarity of the design to the durability of the enamel and plating.

- Affordable Pricing: They offer competitive rates without compromising on quality, making custom enamel pins accessible for businesses, organizations, and individuals alike.

- Timely Delivery: With efficient production processes, they ensure your order is completed and delivered on time, whether you need pins for an upcoming event or a promotional campaign.

Enamel pins are more than just accessories—they’re a blend of art and functionality. By understanding their creation process and leveraging QIYI-GIFTS’ customization services, you can bring your unique designs to life, whether for personal use, brand building, or memorable souvenirs.